Example of Windows Software to Control Hardware:

Computerized INFRARED Heated Rework Station Achieves Faster Throughput: Replaces Large Surface Mount Chips On Dense Printed Circuit Boards More Quickly

PACE IR3000 Software

Our soldering equipment client, PACE Worldwide, wanted to develop a faster rework station that uses infrared energy to melt the solder during the rework process. Trace Systems Inc was involved during the hardware / software co-development process.

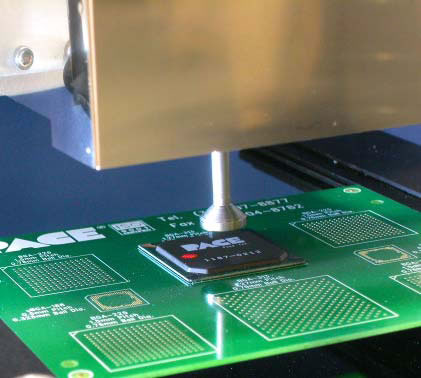

In addition to the same sort of retractable video camera box as is used on the hot air system, the new IR system requires a second video camera to view the IC leads (or Ball Grid Array solder bumps under the chip) to see when the solder melts.

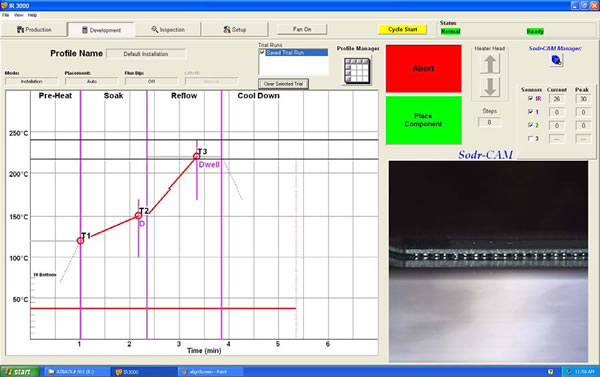

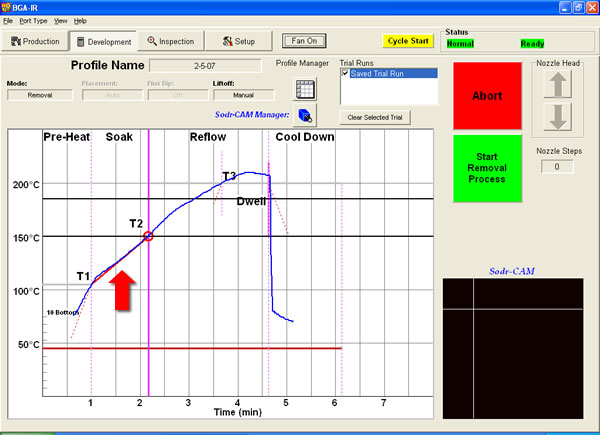

Also, Trace Systems Inc developed a temperature control algorithm that works very well for the unusual requirements of the IR system. Instead of controlling the temperature to stay at a constant temperature value, the IR system requires that the temperature closely match a temperature slope in degrees per second, which is set graphically by the user of the software. The screen show below shows that the temperature control algorithm works remarkably well.

We are pleased to be able to say that our client has had great success with both the hot air and IR versions of their computerized rework station products, and we proud to have been able to help them.

So, how can we help YOU? Contact us and tell us about your needs!